Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material.

Calculate angle to form sheet metal.

Cells on the right will output the desired values.

There are standard charts available with sheet metal design handbook for calculating k factor ideally it should be 0 5.

Work piece the general term for the sheet metal part being bent.

Die edge radius in.

Figure 1 if you know the included bend angle and the die width you can calculate the inside radius and length of the arc at a specific depth of penetration dp using your graphic calculator or online calculators like www handymath.

This estimator calculates a force representative of the pressbrake requirement for air bending.

Actual bending force is affected by many factors such as friction between the material and the die material thickness material strength variations rolling direction of the steel work hardening and other parameters.

The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

Procedure is as below.

In sheet metal design the k factor is used to calculate how much sheet metal one needs to leave for the bend in order to achieve particular final dimensions especially for between the straight sides next the bend.

Punch edge radius in.

So if you got k factor value now you can easily calculate bending allowance.

This type of angle can also be referred to as a square bend.

Straight angle a geometry term for an angle which is equal to 180.

But the most accurate way to find out k factor is reverse engineering of a small but same sheet metal sample piece.

Sizing of a machine or available die width should allow for up to 20.

Tooling general term for the dies punches and holders found on press brake equipment.

Calculate helical screw conveyor in flat form using solidworks sheet metal please subscribe our channel for more videos and projects in solidworks.

A bend greater than 90 but less than 180.

Right angles are the most common feature found in most sheet metal fabrication.

Ultimate tensile strength psi.

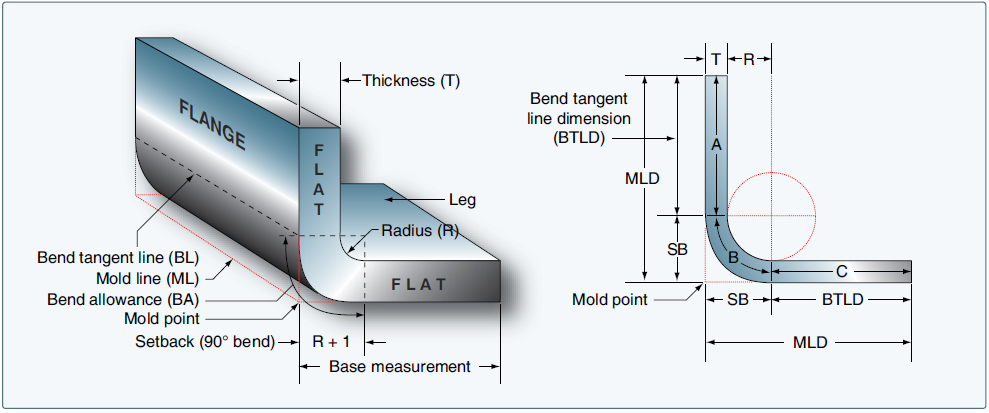

Tonnage charts bend deduction bend allowance and other forming calculations and charts often refer to a 90 bend.

The results give you a starting point for incorporating real world bending variables such as material type thickness springback and the parabola effect.

Tolerances general dimensioning and tolerances of bends and sheet metal.

By doing so the sheet can be bent or stretched into a variety of complex shapes.